source:Industry News release time:2021-09-13 Article author:sznbone Popular:pcb

Almost all printed circuits are required to be printed on the PCB circuit board, with names to identify components, circuits, test points and the printed board itself. The circuit board factory also attaches great importance to this aspect. With curiosity, we walked into the circuit board factory to understand the little knowledge related to printed circuit signs and identification.

In the production of PCB circuit boards, the name can be printed after the printed board is etched, or etched out at the same time as the circuit is etched. If it is printed later, it is usually printed with a silk screen omission process, or stamped with a stamp. In either case, in order to ensure the electrical and chemical properties, the marking material must be carefully selected. Taking into account this principle and some additional process steps involved, usually the designer must have a name on its photographic base map, and etch it out at the same time as the circuit is etched. Although these names are conductive, they generally do not cause problems. The handwriting of the names should be small enough to withstand etching and be clearly visible. The thickness of the copper foil and the position of the name relative to the wire will determine how much the name will be damaged during etching. When using 2 ounces of 3 ounces of copper foil, the name is not clear when it is made very small.

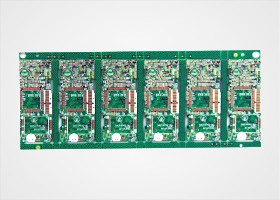

PCB circuit board

In order to facilitate the testing and maintenance of a printed board assembly, as well as to facilitate the visual inspection of the assembly with drawings and data, the reference name mark of the component should be considered. In addition to the reference name sign, the polarity of capacitors and diodes should be pointed out, and they should be marked as close as possible to their mounting holes. The reference name and polarity should be completely visible where the components are placed. The No. 1 lead of the dual in-line integrated circuit should always be marked, and the TO-5 type integrated circuit with the 6, 8, 10 or 12 lead should also be marked.

Printed circuit boards should have two identification marks of different nature, because before the assembly of electrical components, the manufacturer has to machine and plate the printed board, which requires the use of documents and a method of identifying the printed board. One is the manufacturing drawing number of the printed PCB circuit board (original drawing number), and the other is the number of the printed PCB circuit board assembly should also be marked on the component side. The electrical components are assembled on this component side and replaced Spare components are usually tested and repaired here. The number should always be edited by pressing "ASSYNO". In addition, in order to find, the printed board assembly must be numbered consecutively. If space permits, your company name can be displayed on the printed board. All these requirements are easy to do with the etching foil method.

Read recommendations:

Network communication board (sixth floor)

The role of FPC flexible circuit board solder mask.Electronic components PCB

Popular recommended products

High frequency PCB

2021-04-27High frequency PCB

2021-04-27Mobile phone template (six layers)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-27Single-sided double-layer AL base PCB

2021-04-27Aluminum substrate (double-sided)

2021-04-27Silver oil perforated plate (double-sided)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27Single copper base PCB

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-05-24Six-layer Immersion Gold Board (BGA)

2021-05-24Six-layer Immersion Gold Board (BGA)

2021-05-27High frequency PCB

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-27Display board (six layers)

2021-04-27Laminate copper-based PCB after 4L (sample)

2021-04-27High frequency PCB

2021-04-27Network communication board (sixth floor)

2021-04-29Computer card board (four layers)

2021-04-25Six-layer Immersion Gold Board (BGA)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-26DIP plugin

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-26Mobile phone board

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-26Six-layer Immersion Gold Board (BGA)

2021-04-26SMT stickers

2021-05-27SMT stickers

2021-05-27DIP plugin

2021-05-27Mobile phone board

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-26Related Information

The relationship between PCB safety distance and voltage

2024-04-22SMT surface mount processing.Hybrid circuit board PCB

2024-04-15PCB enterprises should pay attention to SMT matters.Electronic components PCB

2024-04-03PCB - the core building block of electronic products.Automotive Electronics PCB

2024-03-25PCB - the bridge and link of the electronic world

2024-03-18How to define high-frequency and high-precision circuit boards.Industrial Electronics PCB

2024-03-11USB PCB interface layout and wiring requirements

2024-01-22Electrolytic capacitor PCB.Steps for using PCB pins

2024-01-15Automotive ElectronicWhat aspects should be considered when processing and manufacturing PCB boards?

2024-01-08Electrolytic capaciWhat is the difference between a gold-plated circuit board and a gold-plated one?

2023-12-25When grinding PCB boards, attention should be paid to.Oscillator (belonging to crystal) PCB

2023-12-18Industrial Electronics PCB!What precautions should be taken when copying and grinding PCB boards

2023-12-11Do you know who is more suitable for LED direct display, regarding the difference between PCB board

2023-12-05Aluminum electrolytic capacitor PCB.What are the standards for selecting PCB boards

2023-11-27Surface Mount Technology (SMT) Phase PCB

2023-11-20Oscillator (belonging to crystal) PCB.The main functions of PCB board

2023-11-13What is the difference between RO filter and PCB filter

2023-11-06Method for determining blind hole PCB board

2023-11-01Electronic Manufacturing Services PCB!What are the effects of PCB board color on performance?

2023-10-23Introduction to the Manufacturing Steps and Requirements of PCBA Test Stand

2023-10-16PCB version maturity stage.AOI circuit board price

2023-09-25How to maintain a PCB circuit board

2023-09-19Development Trend of Printed Circuit Board.Zener diode PCB Vendor

2023-09-14Common problems and cause analysis of PCB circuit board sampling.Zener diode PCB price

2023-09-08What are the issues that need to be understood in PCB circuit board design?IGBT module PCB factory

2023-09-08How to reduce the risk of bending and deformation in PCB circuit board production?Inverter PCB Produ

2023-08-16What are the three main factors that constitute welding defects in PCB circuit boards?Multilayer PCB

2023-08-16The structure of a glass teapot.LCD Module PCB factory

2023-08-11Glass teapot.Inverter PCB Processing

2023-08-11PCB online debugging

2023-08-08