source:Industry News release time:2022-04-15 Article author:yu Popular:pcb

The role and disadvantages of FPC line

1. What is FPC cable?

When it comes to FPC line strips, everyone has no doubt mastered or understood what FPC is? FPC can be divided into many kinds according to its function, such as FPC wireless antenna, FPC touch display screen, FPC capacitive screen, etc. FPC line strip means In one of them, the popularization point, the FPC line is a group of electrode connecting lines that can be bent within a certain level.

2. The composition and main parameters of FPC line

Since the FPC line is a kind of FPC, its composition is the same as that of the FPC. The FPC is generally elongated, and the two sides are designed to be pluggable and fibrous, which can be immediately connected to the RF connector or welded to the commodity. The middle is generally the route. Since the FPC line must have a certain degree of flexibility, the plate is generally made of injection-molded copper, which is resistant to bumps and flexible.

Wire row main parameters:

The minimum graphic boundary line spacing is 3mil/3mil;

The minimum crimping hole for finished products is 0.15mm.

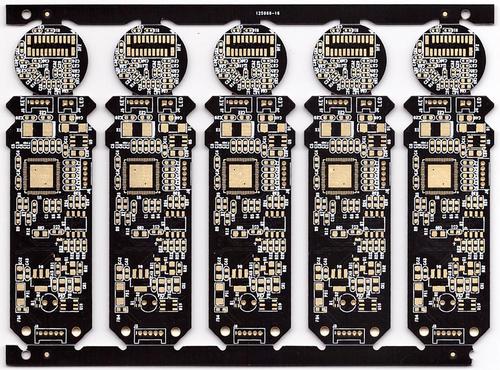

Single-sided FPC bump board

Single-sided FPC bump board

3. FPC line row processing technology

The surface treatment used by FPC line row is generally immersion gold, and sometimes rust is removed. However, the rust removal process cannot be heat-resistant, and the natural environment resistance is worse than that of immersion gold. The price of the two is similar. Therefore, most of them use the immersion gold process. In addition, there are also processing techniques such as electroplating tin and spraying tin, but the high temperature resistance of FPC is generally below 280 degrees Celsius, while the temperature of tin spraying is about 300 degrees Celsius, and as the strength of the solder paste is small, it is also very rarely used.

4. The main purpose of FPC line row

The role of the FPC line depends on the connection of the two related parts or commodities. Nowadays, many products have adopted the wire row. Because of its flexibility, FPC wire row has long been used in many products such as copiers, mobile phones, and notebook computers. The key concentration is in the Pearl River Delta region, in which Shenzhen is the first.

Five, FPC line row advantages and disadvantages

Advantage:

The use of FPC can greatly reduce the volume and net weight of electronic equipment, which is necessary for the development trend of electronic equipment to high density, practicality and high reliability. Therefore, FPC has been widely used in aerospace engineering, national defense, mobile communication, notebook computer, computer peripheral equipment, PDA, digital camera and other industries or commodities. In addition, it can be distributed at will according to the space planning regulations, and can be moved and retracted freely in the three-dimensional space, thereby realizing the integration of the electronic device assembly line and the connection of the transmission line.

defect:

In the whole process of manufacturing goods, cost should be the most difficult problem to consider. Because the flexible fpc is designed and manufactured for unique applications, the initial circuit principle, wiring and photographing bottom plate require higher costs. Otherwise, there is a unique need to use flexible fpc. Generally, it is best not to use it in small quantities. In addition, since a lot of energy has been invested in the work, the maintenance in the middle and later stages is of course indispensable, so soldering and rework must be practiced by well-trained staff.

Storage of FPC line

Unlike other products, FPC flexible circuit boards cannot actually come into contact with gas and water. So how should people properly store such goods? I believe that after reading the following points, you will find the reference answer.

First, the vacuum pump of the FPC flexible circuit board cannot be destroyed. When loading the car, a layer of bubble pad must be placed next to the small box. The bubble pad has a better water absorption capacity, which has a very good effect on waterproofing. Perhaps, waterproof beads All are indispensable.

Secondly, after the Gangsi Festival, the small box must be partitioned off the wall, stored away from the ground in a dry and cool place, and protected from sunlight. The temperature of the warehouse is best controlled at 23±3℃, 55±10%RH. Under such standards, PCB boards with metal surface treatments such as immersion gold, electro-gold, spray tin, nickel plating/silver plating can generally be stored for 6 months. , Immersion silver, immersion tin, OSP and other metal surface-treated PCB boards can generally be stored for 3 months.

Read recommendations:

Six-layer Immersion Gold Board (BGA)

Gigabit Ethernet PCB Layout Guidelines.Electronic Manufacturing Services PCB

Popular recommended products

Six-layer Immersion Gold Board (BGA)

2021-05-24Laminate copper-based PCB after 4L (sample)

2021-04-27Silver oil perforated plate (double-sided)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27Single copper base PCB

2021-04-27Aluminum substrate (double-sided)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-24High frequency PCB

2021-04-27Mobile phone template (six layers)

2021-04-27High frequency PCB

2021-04-27Computer card board (four layers)

2021-04-25Single-sided double-layer AL base PCB

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-27Display board (six layers)

2021-04-27Network communication board (sixth floor)

2021-04-29High frequency PCB

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27High frequency PCB

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27SMT stickers

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-26Six-layer Immersion Gold Board (BGA)

2021-04-26SMT stickers

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-26DIP plugin

2021-05-27Mobile phone board

2021-04-27Mobile phone board

2021-05-27DIP plugin

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-26Six-layer Immersion Gold Board (BGA)

2021-04-26Related Information

The relationship between PCB safety distance and voltage

2024-04-22SMT surface mount processing.Hybrid circuit board PCB

2024-04-15PCB enterprises should pay attention to SMT matters.Electronic components PCB

2024-04-03PCB - the core building block of electronic products.Automotive Electronics PCB

2024-03-25PCB - the bridge and link of the electronic world

2024-03-18How to define high-frequency and high-precision circuit boards.Industrial Electronics PCB

2024-03-11USB PCB interface layout and wiring requirements

2024-01-22Electrolytic capacitor PCB.Steps for using PCB pins

2024-01-15Automotive ElectronicWhat aspects should be considered when processing and manufacturing PCB boards?

2024-01-08Electrolytic capaciWhat is the difference between a gold-plated circuit board and a gold-plated one?

2023-12-25When grinding PCB boards, attention should be paid to.Oscillator (belonging to crystal) PCB

2023-12-18Industrial Electronics PCB!What precautions should be taken when copying and grinding PCB boards

2023-12-11Do you know who is more suitable for LED direct display, regarding the difference between PCB board

2023-12-05Aluminum electrolytic capacitor PCB.What are the standards for selecting PCB boards

2023-11-27Surface Mount Technology (SMT) Phase PCB

2023-11-20Oscillator (belonging to crystal) PCB.The main functions of PCB board

2023-11-13What is the difference between RO filter and PCB filter

2023-11-06Method for determining blind hole PCB board

2023-11-01Electronic Manufacturing Services PCB!What are the effects of PCB board color on performance?

2023-10-23Introduction to the Manufacturing Steps and Requirements of PCBA Test Stand

2023-10-16PCB version maturity stage.AOI circuit board price

2023-09-25How to maintain a PCB circuit board

2023-09-19Development Trend of Printed Circuit Board.Zener diode PCB Vendor

2023-09-14Common problems and cause analysis of PCB circuit board sampling.Zener diode PCB price

2023-09-08What are the issues that need to be understood in PCB circuit board design?IGBT module PCB factory

2023-09-08How to reduce the risk of bending and deformation in PCB circuit board production?Inverter PCB Produ

2023-08-16What are the three main factors that constitute welding defects in PCB circuit boards?Multilayer PCB

2023-08-16The structure of a glass teapot.LCD Module PCB factory

2023-08-11Glass teapot.Inverter PCB Processing

2023-08-11PCB online debugging

2023-08-08